Natural Gas generating stations

The Upper Peninsula of Michigan was in need of a long-term, reliable, affordable and clean energy solution. Upper Michigan Energy Resources responded to that need by providing the natural gas-fueled F.D. Kuester Generating Station and A.J. Mihm Generating Station.

Location

These natural gas-fueled generating stations are located in the Upper Peninsula of Michigan: F. D. Kuester Generating Station in Negaunee Township (near Marquette), and A. J. Mihm Generating Station in Baraga Township (near L’Anse).

Description

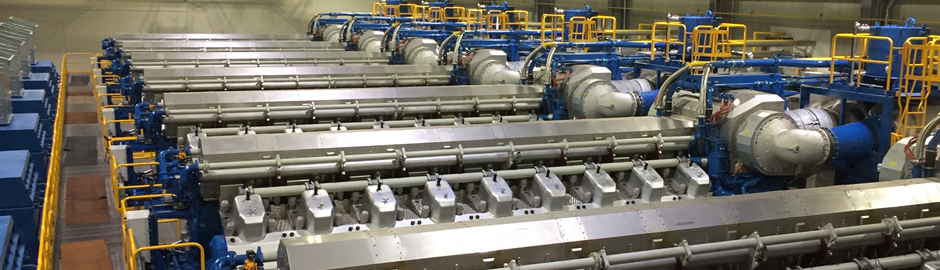

The seven units at F.D. Kuester Generating Station and the three units at A.J. Mihm Generating Station use a technology known as RICE – reciprocating internal combustion engines. RICE units are becoming increasingly common on utility power systems due to their high efficiency, modular construction and flexibility of operations. Fueled with natural gas, each engine is shaft-coupled to an electric generator. The RICE units are housed inside a building with an exterior resembling a warehouse. The exhaust system is located outside the building and includes silencers, air quality control systems and stacks.

Sound attenuation

UMERC worked with the engine manufacturer and an engineering firm to design each generating station with a 50-decibel sound limit – which is similar to the sound made by a household floor fan. Some of the features include concrete walls with interior sound attenuation panels, a double-layer roof, using heavy-duty steel panels with sound attenuation, silencers on air intake and exhaust systems and ultra-low-noise radiators. Sound testing results indicate the facilities each operate between 25 and 36 decibels – below the targeted 50-decibel limit.

Cost

Approximately $275 million

Engines

Each engine is 46 feet long and 20 feet tall and weighs approximately 325 tons.

Fuel

Natural gas

Commissioning

All 10 engines were placed into service in March 2019.

Generating capacity

Each of the 10 engines has a gross generating capacity of 18.9 megawatts (MW).

Total net generating capacity

- F.D. Kuester Generating Station: 128.1 MW

- A.J. Mihm Generating Station: 54.9 MW

Average fuel use

Each engine has a full-load consumption of natural gas of 152 dekatherms per hour.

Stack

The seven engines at F.D. Kuester Generating Station are ducted to a single, common 130-foot stack. Each of the three engines at A.J. Mihm Generating Station has its own 65-foot stack.

Air quality control system

The stations use selective catalytic reduction with urea injection for control of nitrogen oxides and an oxidation catalyst for control of carbon monoxide, volatile organic compounds and hazardous air pollutants.

Cooling system

Each engine is cooled by 24 radiator fans that reject heat from a closed-loop circulating antifreeze (coolant) system. F.D. Kuester Generating Station has a total of 168 fans, and A.J. Mihm Generating Station has a total of 72 fans.

Remote control operations

All major functions in the generating station are monitored and controlled remotely by operators from Green Bay and Milwaukee, Wisconsin. Local, plant-based computer controls support the operation by continuously monitoring and reporting ignition conditions, pressures, temperatures, flow rates, etc. Both facilities employ total remote start, stop and loading functionality, with on-site personnel focused on maintenance and support activities.

Milestones

| April 2018 | Site preparation completed |

| May 2018 | Engines delivered in L’Anse |

| June-July 2018 | Engines delivered to Negaunee site |

| September 2018 | Engines delivered to Baraga site |

| September 2018 | Engine halls completed |

| October 2018 | SEMCO gas pipeline completed |

| December 2018 | Construction completed |

| January-March 2019 | Commissioning and testing |

| March 31, 2019 | Commercial operation – facilities provide power to grid |